Water electrolysis comprises the splitting of water molecules into their constituent parts (H2 and O2) by passage of an electrical current.

There are two main electrolyser technologies – alkaline, which contain liquid electrolytes (potassium or sodium hydroxide), and solid polymer electrolyte electrolysers (PEM).

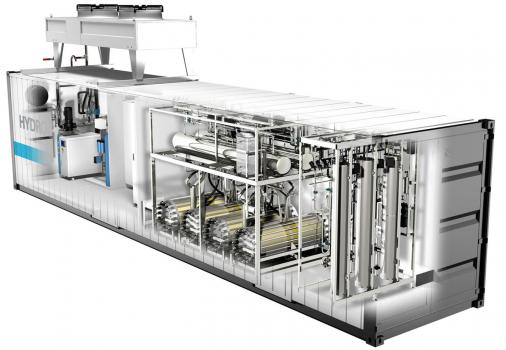

Besides the electrolyser unit, an on-site station generating hydrogen by electrolysis requires water purification systems and a hydrogen purification and drier unit to treat the hydrogen produced.

Many electrolysers generate hydrogen at relatively low pressure, e.g. 10 to 25 bar, so further compression is required to elevate the pressure to storage pressures.

Within the framework of the EU’s targets of 20% renewable energy for electricity production and 10% renewable energy in transport by 2020, on-site production of hydrogen via electrolysis from renewable energy sources is an attractive solution. The use of hydrogen as a clean energy carrier, enables storage of large quantities of energy for longer periods of time, and can play an important role in stabilising the grid when the contribution of highly intermittent energy sources increases.

If this electricity is produced from renewable energy, the resulting hydrogen is “green” and “zero- emission from well to wheel.